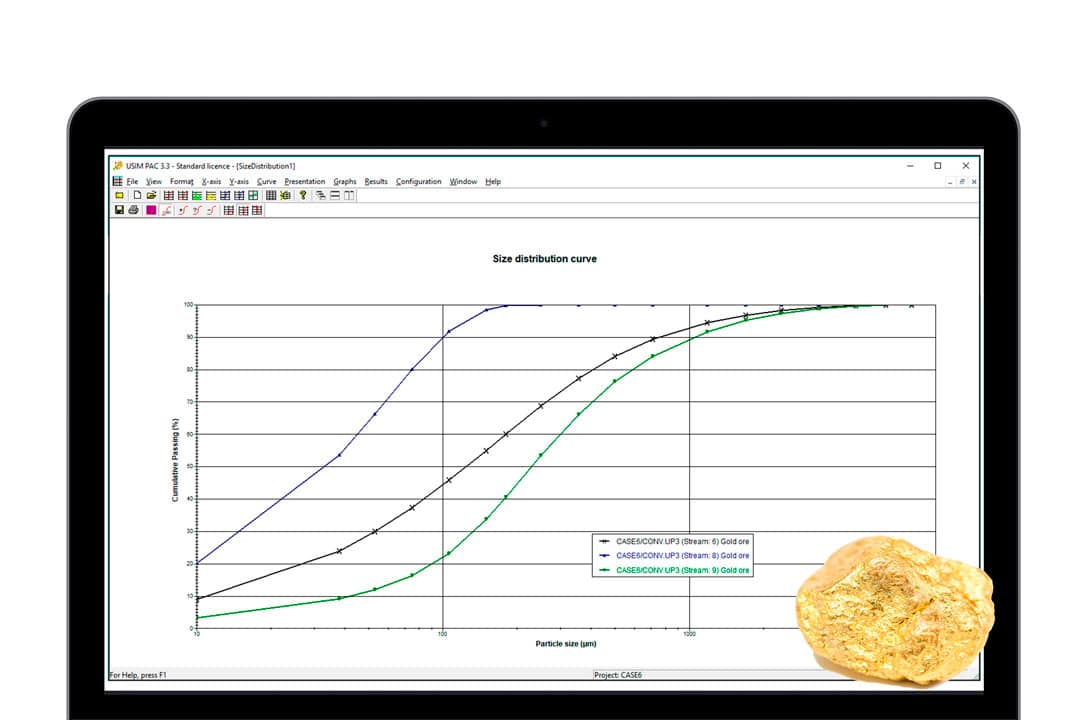

USIM PAC: process modeling and simulation software

Empower engineering decisions. Improve efficiency and profitability of your processing plant. Better, faster and safer.

USIM PAC is a steady-state process modeling and simulation software to design, analyze and optimize industrial processes. In a single interface, USIM PAC performs mass balancing, modeling and simulation of all the streams and unit operations of your processing plant. USIM PAC is a unique engineering software. It relies on a detailed and configurable characterization of material. Thus, it is particularly suitable if you deal with solids and complex mixtures, difficult to describe as pure substances.

Ready to speed up your process development with USIM PAC?

Overview

Features

For who

Services

Improve overall plant performance from lab to plant with our simulator

USIM PAC is a complete software platform for modeling and simulation of industrial processes.

It performs simulation, data reconciliation, mass balancing, flowsheeting, equipment sizing, economic and environmental calculations and off-line process optimization in a single environment for overall plant or part thereof.

USIM PAC relies on a unique approach to characterize solids and mixtures considering multi-component and multi-streams with phase changes.

Our process simulator has been originally designed for mineral processing and hydrometallurgy. It is the only software on the market able to model in one platform nearly all the mine-to-mill processing operations from crushing to refining passing through grinding, gravity and magnetic separation, flotation, leaching and concentration.

All-in-one process engineering tool

Technical, economical and environmental calculations

Fine description

of the material

Definition of physical properties, phase changes, particle size distribution…

Flexible library of models

Built-in set of +150 unit operation models with different levels and ability to create your own models

Highly configurable

Available in various languages, can be customized following your own specifications

Continuous & batch processes

A single environment to manage any type of process

With USIM PAC process simulator, solve any engineering problem

Process design and analysis

- Build a digital twin

- Define the main treatment stages to reach a set of given

objectives - Derive the forecasted material balances for each stream

(mass, energy, water…) - Size units of equipement and define the settings

- Quickly assess configurations

- Evaluate the process flexibility

- Estimate CAPEX and OPEX parameters

- Derive technical and economic feasibility studies

Process monitoring and optimization

- Reduce pilot and industrial tests and their risk

- Make easier technology transfer and scale-up

- Increase productivity and reduce costs

- Better understand your process

- Monitor performance (yields, losses…)

- Evaluate, limit energy, water and reagents consumption

- Adapt processes to the raw material variability

- Identify bottlenecks

- Improve the final product quality

- Move from batch to continuous process

Develop and optimize your process with all-in-one engineering toolbox

-

A simulator for all the process engineering stages

USIM PAC improves efficiency during process design, plant sizing, plant survey, process optimization.

It ensures smooth scale up from lab to pilot and from pilot to plant. USIM PAC can also be very helpful for educational purpose or in the frame of R&D projects in process engineering.

-

An integrated process simulation software

USIM PAC is not only a tool to predict and optimize entire process plants. It allows to balance, model, simulate batch or continuous process in a single interface.

USIM PAC allows process engineers and scientists to:

- model plant operations using available experimental data

- determine optimal plant configuration that meets production targets

- size unit operations required to achieve given circuit objectives.

Simulation

Equipment sizing & optimization

Sensitivity analysis

Environmental calculations

Capital cost estimation

USIM PAC is a process simulator used by engineers in more than 50 countries.

Better characterize materials to achieve accurate process design

-

A unique approach in material modeling

With USIM PAC, take into account the complexity and the variability of your materials: heterogeneity, components, composition, phases, phase transfer… Unlike most chemical process simulators, our process modeling and simulation software does not require the use of thermodynamic databases.

USIM PAC simulator is particularly suitable when processing raw materials, solids or solids and liquid mixtures, like ores, biomass, waste.

-

Combine all information into a single model

With USIM PAC, evaluate raw material, products, reagents, water, wastes… on a stream by stream basis for the entire plant.

USIM PAC also back-calculates data which cannot be measured.

Discover USIM PAC engineering software through a self-paced online course

Speed up process development and optimization

-

Built-in unit operations library

More than 150 unit operation models are available in order to complete daily tasks more quickly. USIM PAC includes models dedicated to various industrial fields such as comminution, physical separation, solid/liquid separation, membrane technologies, hydrometallurgy, biotechnology…

Mathematical models calculate the output streams data from the input streams data and model parameters. These parameters can be equipment sizes, operating settings and conditions, physical properties, model adjustment parameters or simply performance criteria.

-

Open process modeling software

With USIM PAC, you can create your own equipment models to suit process conditions and represent accurately your plant.

+150 models of unit operation models: physical, thermal and biological processes

- Crushing

- Grinding mills, SAG

- Screening

- Hydro-classification

- Hydrocyclones

- Dense medium separation

- Gravity separation

- Magnetic separation

- Flotation cells and columns

- Mineral liberation

- Leaching and bioleaching

- Precipitation

- Adsorption : CIP, CIL, resins

- Solvent extraction, SX

- Cementation

- Electrolysis, EW

- Thickeners and decantors

- Filtration and ultra-filtration

- Diafiltration

- Membrane separation

- Sorting

- Batch extraction

- Centrifugation

- Reactive extrusion

- Collection

- Composting

- Incineration

Empower engineering decisions and collaborations with our process engineering software

-

A user-friendly process simulation software

USIM PAC includes a set of data representation tools: process flow diagrams, curves, data displays.

With USIM PAC, export all data tables as spreadsheets.

A highly efficient communication vector

USIM PAC facilitates the communication between the different actors who play a part in the plant life.

Graphical representations allow you to document your decisions and deliver dashboard for management.

Still using spreadsheets for modeling and simulation of your process?

Explore a new way to analyze, design and optimize your processes with USIM PAC.

We chose USIM PAC, a modeling and simulation software based on a technology well established in the mineral industry. Starting from a raw material to converge towards constituents of interest…. The similarity of our resources with minerals seduced me.

From mineral processing to any industry involving solids and mixtures

Initially developed for mineral processing and hydrometallurgy 30 years ago, USIM PAC flexible structure has been allowing to approach all industries processing natural, variable and heterogeneous materials.

Mining

and metallurgy

- Iron ores, base and precious metals

- Industrial minerals

- Building materials

- Phosphate, potash, uranium, coal…

Food processing

and biorefinery

- Biomass: algae, wood, oilseed, grains…

- Food: milk, proteins, natural ingredients…

Waste and waste water treatment

- Municipal solid wastes (MSW)

- Waste electrical and electronic equipment (WEEE)

- Waste water…

Other industrial processes

All processing plant dealing with solids and mixtures, particularly heterogeneous (inks, cosmetics, pharmaceuticals…)

Associated services

for USIM PAC process modeling and simulation software

Consulting

Support

Courses

Related articles

CASPEO is proud to announce the launch of CASPEO DAYS 2024, a conference dedicated to exploring the future of mining

CASPEO DAYS 2024 will explore the pivotal role of data reconciliation. It will be focused on the data quality and how to achieve it… On the Path Towards Intelligent Mining!

CASPEO celebrates its 20th anniversary in 2024

This year, CASPEO is celebrating its 20th anniversary, marking two incredible decades of innovation, growth, and success in the mining industry. A celebration marked by a conference "On the path...

Master II Internship – Modeling of hydrometallurgical operations: solvent extraction

CASPEO develops and distributes the USIM PAC software, a static process simulator for the design and optimization of mineral processing and hydrometallurgical plants. Hydrometallurgical operations...

Ready to talk about your project?

Question about your process, our process simulation software or services? Write us here to be in touch.

Subscribe to our newsletter

CASPEO provides trusted process design and optimization services and simulation software to engineers dealing with solids and all types of raw materials. With CASPEO, go beyond process simulation.

Stay tuned!

Empower your decisions

Consulting

Engineering software

Get a quote

Develop your skills

Blog

Get a live demo

Need assistance?

On-line support

Contact us

2024 © CASPEO - All rights reserved